- HOME

- Know Your Tech

- Supply chain management for SME: Challenges and best practices

Supply chain management for SME: Challenges and best practices

- Last Updated : February 2, 2026

- 446 Views

- 11 Min Read

SME operations typically begin simply, with one supplier, manageable inventory, and orders you can track easily. Then you add a second supplier, expand product lines, and suddenly lose visibility into what's where and when it's arriving.

Highlights

- SMEs face unique supply chain challenges, like limited visibility, resource constraints, and supplier dependency—all of which impact operations differently than large enterprises.

- Supply chain management connects procurement, inventory, warehousing, and logistics into one coordinated system that works together.

- Real-time visibility across all operations helps you spot issues before they affect customers and make faster decisions based on current data.

- Common problems, like cash flow pressures and demand unpredictability, can be solved through better forecasting and strategic planning.

- Starting with inventory tracking delivers immediate benefits and creates a foundation for coordinating other supply chain phases.

A breakdown in visibility results in significant costs through stockouts, duplicate orders, and customers waiting for answers you can't quickly provide. Effective supply chain management gives SMEs the clarity to make quick decisions and provides the systems to execute them reliably.

This blog post explains what supply chain management means for SMEs, the unique challenges they face, and strategies to build efficient operations that support growth without adding complexity.

What is supply chain management for SMEs?

Supply chain management for SMEs means coordinating how products move from suppliers to customers using systems that match your limited resources.

Unlike large enterprises with dedicated supply chain teams, small businesses manage procurement, inventory, warehousing, and delivery with a small team responsible for multiple functions.

When implemented right, supply chain management helps SMEs compete with larger businesses. You gain the operational clarity that bigger competitors have, but with tools and approaches that fit your budget and team size.

For example, when inventory drops below set levels, automated systems can place supplier orders without someone manually checking stock daily, freeing your team for customer-facing work that actually grows the business.

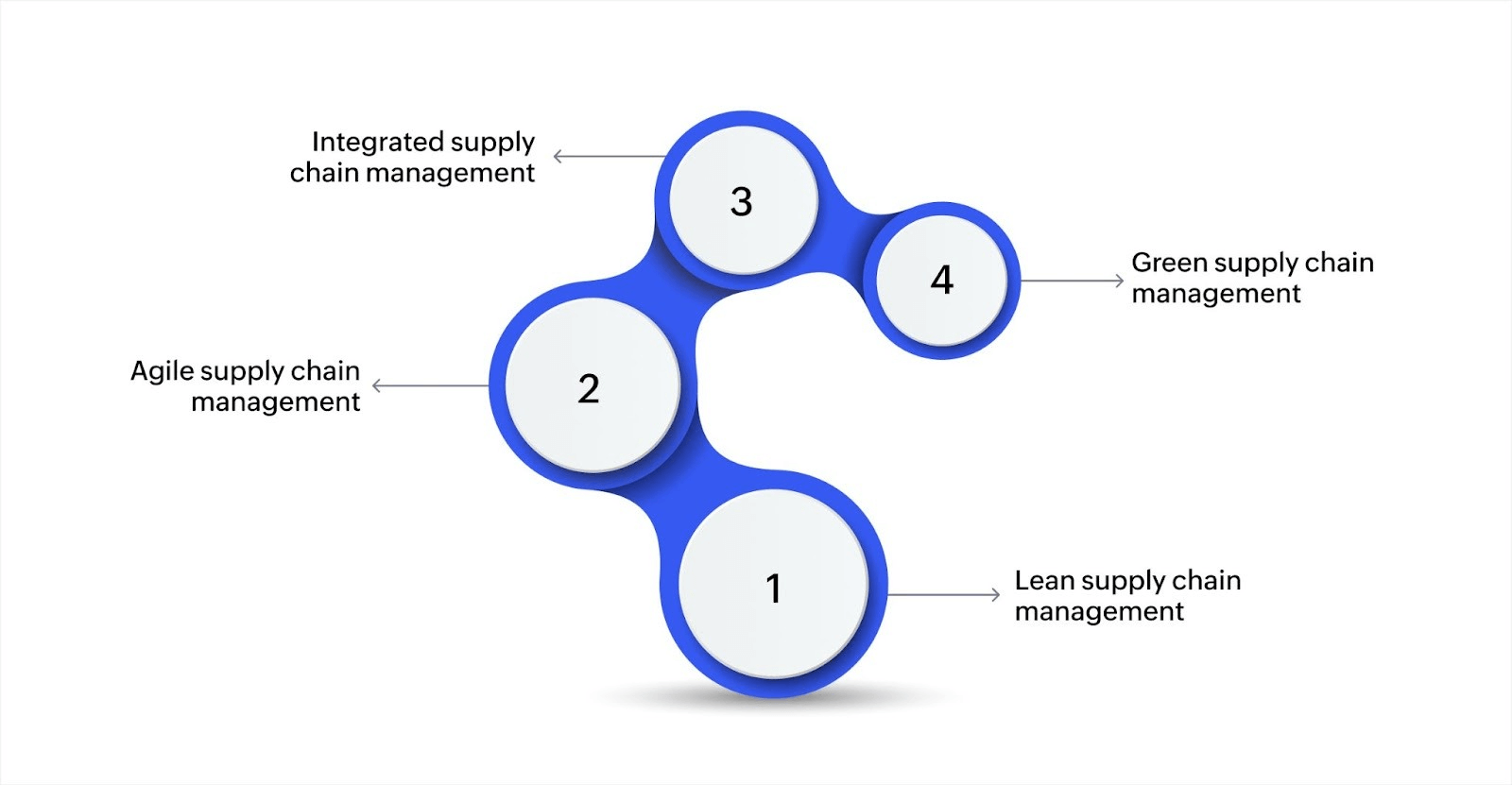

Different forms of supply chain management

Depending on business needs, there are different ways to approach supply chain management for SMEs:

- Lean supply chain management focuses on cutting waste and improving efficiency. It aims to produce and deliver only what is needed, when it’s needed, reducing excess inventory and speeding up delivery times.

- Agile supply chain management emphasizes flexibility. It prepares businesses to quickly respond to changes in demand or disruptions, making it ideal for industries where customer preferences shift often.

- Integrated supply chain management takes a holistic view, connecting all partners in the chain through shared information and collaborative planning. This approach reduces silos and fosters better decision-making.

- Green supply chain management adds an environmental focus, aiming to minimize the ecological footprint of sourcing, production, and distribution activities.

Each approach addresses specific challenges, but all share the goal of improving visibility, control, and efficiency across the supply chain.

Key components of supply chain management

Understanding these five key SCM components helps you pinpoint high-impact improvements:

| Component | What it involves | Why it matters for SMEs |

| Planning and forecasting | Predicting demand, scheduling production, coordinating resources | Prevents overstock that ties up cash or stockouts that lose sales |

| Procurement | Selecting suppliers, negotiating terms, placing orders, managing contracts | Strong supplier relationships ensure quality materials arrive on time at competitive prices |

| Inventory management | Tracking stock levels, monitoring movement, managing storage | Accurate inventory prevents both excess storage costs and missed sales opportunities |

| Warehousing | Receiving goods, organizing storage, preparing for shipment | Efficient warehousing speeds up fulfillment and reduces damage or loss |

| Logistics and distribution | Managing transportation, tracking shipments, coordinating deliveries | Reliable delivery builds customer trust and reduces complaints |

These components work together as a connected system. When one phase faces problems, it affects everything downstream. For instance, poor demand forecasting leads to inventory imbalances, which creates warehousing issues and ultimately delays customer deliveries.

Example of the supply chain management process for SMEs

Let’s say you run a business that sells eco-friendly home cleaning products. You source ingredients like natural oils and plant-based surfactants from suppliers in different regions. You also rely on packaging vendors, manufacturing partners, warehousing providers, and a delivery service to get the final product to your customers.

Without supply chain management, here’s what might happen: You place orders manually. Inventory tracking is done in spreadsheets. One supplier misses a shipment, but no one notices until your warehouse runs low. Production gets delayed. Customer orders pile up—and you’re left scrambling to find out what went wrong and where.

Here’s how the same scenario looks with an SCM system in place:

- As soon as your inventory of ingredients drops below a set level, the system can be set to automatically send out a purchase order.

- Real-time tracking can be set to see if a shipment is delayed and alert you before it becomes a problem.

- Production can be planned based on available inventory and current demand, keeping output consistent.

- Your team will know exactly what’s in stock, what’s in transit, and when orders will be fulfilled.

- Customers will receive updates on their orders and get them on time.

In short, the entire process, from sourcing to delivery, becomes connected, transparent, and manageable.

Why supply chain management matters for SMEs

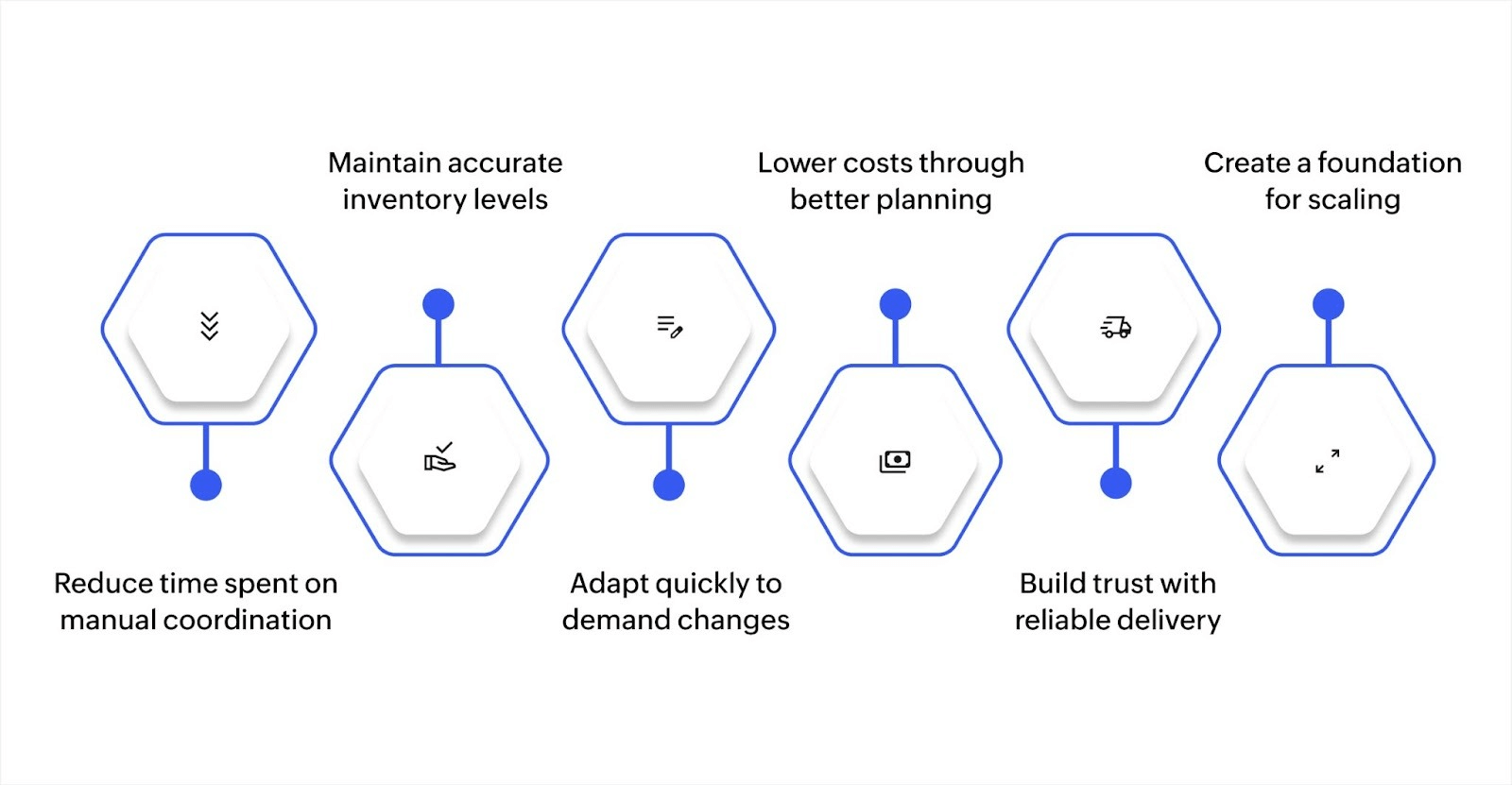

Growing businesses reach a point where spreadsheets, manual tracking, and coordination via phone calls become ineffective. Supply chain management brings structure and visibility to operations, helping you move from reactive firefighting to proactive control. Here's what proper supply chain management provides:

Reduced time spent on manual coordination

Coordinated systems reduce time spent on manual tasks like updating inventory spreadsheets, chasing supplier updates, or reconciling order records. Teams spend less time on administrative work and more time on activities that directly serve customers or improve operations.

Accurate inventory levels

Real-time tracking shows exactly what's in stock, what's on order, and when deliveries arrive. This visibility prevents situations where you turn down orders because systems show no stock while products sit in your warehouse, or where you order more supplies when adequate inventory already exists.

Adapting quickly to demand changes

When demand spikes unexpectedly or suppliers face delays, connected systems help you adapt quickly. You can adjust orders, find alternative suppliers, or prioritize urgent customer needs based on current data rather than outdated information.

Lowered costs through better planning

Better coordination reduces waste from overstocking, minimizes rush shipping fees from poor planning, and prevents lost sales from stockouts. Accurate demand forecasting helps negotiate better supplier terms through consistent order volumes.

Trust built from reliable delivery

Reliable delivery builds trust. When you consistently meet promised delivery dates and communicate proactively about any changes, customers view your business as dependable. Supply chain visibility lets you provide accurate delivery estimates and updates.

A foundation for scaling

As your business scales, proper supply chain management supports increased volume without proportionally increasing coordination overhead. Systems that work for 100 orders monthly can handle 1,000 orders with adjustments rather than requiring complete operational overhauls.

Common supply chain challenges SMEs face and solutions

Small and medium businesses face different supply chain issues than large enterprises. Limited resources, smaller teams, and tighter budgets mean challenges that might be minor inconveniences for big companies can significantly impact SME operations. Here are the specific challenges SMEs typically come across:

Limited visibility across operations

Many SMEs track different supply chain phases in separate systems or spreadsheets. Procurement records exist in one place, inventory in another, and customer orders in a third system. This fragmentation makes it difficult to see the complete picture or identify where bottlenecks occur.

Solution: Integrate these systems using software to resolve visibility issues immediately. Real-time dashboards show inventory, orders, and shipments in one view, so you can spot issues before they affect customers. You get the complete picture without jumping between tools.

Resource constraints

SMEs rarely have dedicated supply chain teams or specialists. The same people handling sales might also manage inventory, while owners often handle supplier relationships alongside other responsibilities. This stretched capacity makes coordinated planning difficult.

Solution:Automation can handle the repetitive coordination work your team does manually. Systems send purchase orders, update inventory counts, and notify the right people when actions are needed so your team can focus on decisions that actually require human judgment. In fact, data from a recent survey shows that 53% of participants reported using AI automation to manage supply chain disruptions.

Cash flow pressures

Limited working capital affects purchasing decisions. You might need to buy smaller quantities more frequently, losing volume discounts. Or you might delay necessary purchases until cash arrives, risking stockouts. These constraints make inventory optimization critical yet challenging.

Solution: Better demand forecasting helps you plan purchases around cash availability. When you know what you'll need and when, you can negotiate payment terms with suppliers that match your cash flow. Accurate data removes guesswork from purchasing decisions.

Supplier dependency

Relying on one or two key suppliers creates vulnerability. If a supplier faces production issues or delays, you have limited alternatives. Building relationships with multiple suppliers requires time and resources that SMEs often lack.

Solution: Start developing backup supplier relationships before you need them. Even if one supplier handles most orders, having tested alternatives provides security. When your primary supplier knows you have options, service often improves too.

Demand unpredictability

Without sophisticated forecasting tools, SMEs often struggle to predict demand accurately. Seasonal variations, market changes, or unexpected orders create planning challenges. This uncertainty makes it hard to maintain optimal inventory levels.

Solution: Historical sales data reveals patterns you can use for forecasting. Track what's sold when, identify seasonal trends, and adjust for known events like promotions. Even basic analysis beats ordering based on gut feeling alone.

Manual coordination overhead

Phone calls, emails, and spreadsheet updates consume significant time. Coordinating between suppliers, warehouses, and customers through manual processes creates delays and increases the risk of error. Information gaps occur when updates don't reach all relevant parties.

Solution: Digital systems share information automatically across your team. When a shipment arrives, everyone who needs to know gets notified instantly. When inventory drops, purchase orders trigger without someone having to remember to check levels.

Best practices for implementing supply chain management

Transitioning from disconnected processes to coordinated supply chain management is most effective when done systematically. Starting with high-impact areas and expanding gradually prevents disruption while delivering measurable improvements. Here are some effective approaches SMEs can follow:

Map your current processes

Document how materials currently flow through your business. Track where information lives, who handles each step, and where delays typically occur. This mapping reveals bottlenecks and redundancies that proper systems can address.

Start with inventory visibility

Implementing real-time inventory tracking delivers immediate benefits. Knowing current stock levels, what's on order, and expected arrival dates reduces guesswork and prevents costly mistakes. This foundation supports better decisions across other supply chain phases.

Connect with key suppliers digitally

Move supplier communication from phone and email to shared systems where both parties can see order status, delivery schedules, and any issues. This transparency reduces coordination time and catches problems earlier.

Use data for demand planning

Analyze past sales patterns, seasonal trends, and growth trajectories to forecast future demand more accurately. Even basic data analysis improves ordering decisions compared to intuition alone. Adjust forecasts regularly as you gather more information.

Automate routine coordination tasks

Systems can handle repetitive work like sending order confirmations, updating inventory counts, or notifying relevant teams when shipments arrive. Automation reduces manual effort and ensures consistent execution.

Build supplier relationships proactively

Regular communication with suppliers, even when no immediate issues exist, strengthens partnerships. Share your growth plans and demand forecasts so suppliers can plan accordingly. Strong relationships provide flexibility when urgent needs arise.

Review and adjust regularly

Supply chains require ongoing attention. Schedule regular reviews of inventory turnover, supplier performance, delivery times, and cost trends. Use these insights to refine processes and address emerging issues before they become critical.

What is supply chain management software?

Supply chain management software (SCMS) is a digital solution that helps businesses manage and coordinate every part of their supply chain. It acts as a central hub, connecting data, teams, and processes to make the entire operation more predictable, trackable, and efficient.

These tools help businesses improve order accuracy, reduce stockouts, forecast demand more reliably, and streamline fulfillment.

How does supply chain management software work?

Supply chain management software works by bringing your entire supply process into a connected, digital system. It tracks every stage, from procurement and production to warehousing and delivery. You can monitor what's happening in real time and act quickly when needed.

At its core, SCMS offers:

- Centralized visibility: Instead of jumping between spreadsheets or chasing updates over email, you get one dashboard with all the data. It includes orders, inventory levels, supplier updates, and shipment tracking.

- Real-time tracking and alerts: Whether it’s a shipment delay or a drop in stock levels, the system sends timely notifications so you can respond without missing a beat.

- Automation of repetitive tasks: From generating purchase orders to updating inventory counts, the software handles routine operations. This reduces manual errors and saves hours of admin work each week.

- Data-backed decision-making: With built-in analytics and custom reports, you can forecast demand, plan purchases better, and make smarter decisions about stock and fulfillment.

Take Chhabra Brothers, for example, a growing distribution business that needed more than just spreadsheets to manage its expanding operations. By using Zoho Creator, a low-code, AI-powered app development platform, they built a custom ERP that brought together purchase management, inventory tracking, accounting, and delivery scheduling into a single system.

As a result, they experienced faster decision-making, better inventory control, and a supply chain that runs more smoothly, all without adding new layers of complexity.

How to choose the right supply chain management software

Selecting the appropriate supply chain management software is a critical decision that can impact your SME's efficiency and growth. To make an informed decision, consider these key steps:

1. Assess your business needs and objectives

Identify the main challenges in your supply chain, such as inventory management, order fulfillment, or supplier coordination, and set clear short-term and long-term goals for improvement.

2. Compare different software solutions and providers

Look for software that offers the essential functions you need, like real-time tracking, demand forecasting, and seamless integration with your existing systems. Also, make sure the interface is intuitive so your team can adopt it easily.

3. Consider scalability and future growth

Choose a platform that can be tailored to your unique processes and scale with your business as it grows in volume, complexity, and user base.

Build custom supply chain solutions with Zoho Creator

Many SMEs find that generic supply chain software either lacks necessary capabilities or includes unnecessary complexity that doesn't match their operations. Standard systems often force businesses to adapt their processes to fit the software rather than the reverse.

Zoho Creator helps you build supply chain management applications tailored to your specific requirements. You can create custom solutions for procurement tracking, inventory management, supplier coordination, and order fulfillment that match exactly how your business operates.

The platform lets you design automated workflows, build mobile apps for real-time updates, connect with existing systems through integrations, and create dashboards that provide complete visibility across your operations.

Growing SMEs need supply chain solutions that adapt to their unique operations. Start your 15-day free trial and build the supply chain management system your growing business needs.

FAQ

1. What's the first step in improving supply chain management?

Start by mapping your current processes to identify where delays, errors, or visibility gaps occur. Focus initial improvements on areas causing the most operational pain, such as inventory visibility or supplier coordination, rather than trying to address everything simultaneously.

2. How long does it take to see results from supply chain improvements?

Basic improvements like implementing inventory tracking can show results within weeks through reduced stockouts and better ordering decisions. More comprehensive changes that coordinate multiple supply chain phases typically demonstrate clear benefits within a few months.

3. Do SMEs need dedicated supply chain software, or can they use spreadsheets?

Spreadsheets work for very small operations but create coordination problems as businesses grow. Multiple people accessing and updating spreadsheets leads to version conflicts, errors, and limited real-time visibility. Proper systems become essential as complexity increases.

4. Is implementing supply chain management costly for small businesses?

Costs vary based on business size and chosen approach. Cloud-based solutions with monthly subscriptions start affordably for basic needs. Custom solutions built on low-code platforms scale with your business, avoiding large upfront investments while providing exactly what you need.

5. What supply chain metrics should SMEs track?

Focus on metrics that directly impact operations: inventory turnover, order fulfillment time, supplier on-time delivery rates, order accuracy, and carrying costs. These indicators reveal performance trends and highlight areas needing attention without requiring complex analysis.

Merlin

MerlinMerlin is our in-house digital workplace content specialist. She spends part of her days combining her passion for writing with marketing. The rest of her time is spent reading manga, battling friends in online games, and discovering new music.