- HOME

- Know Your Tech

- What is supply chain management? Types and best practices

What is supply chain management? Types and best practices

- Last Updated : February 2, 2026

- 575 Views

- 11 Min Read

How do you coordinate suppliers, manufacturers, warehouses, and delivery teams while keeping costs down and customers satisfied? For many businesses, managing this flow creates constant challenges, including missed shipments, excess inventory, rising expenses, and frustrated customers.

Highlights

- Supply chain management coordinates all activities moving products from suppliers to customers, covering planning, procurement, production, logistics, and returns.

- Effective management reduces operational costs, improves visibility, handles disruptions better, and supports business growth without proportional expense increases.

- Four key flows work together in supply chains: product movement, information sharing, financial transactions, and reverse logistics for returns.

- Best practices focus on data-driven decisions, strong supplier relationships, cross-functional coordination, efficient inventory management, and continuous improvement.

- Low-code platforms let businesses build custom supply chain solutions without extensive coding, matching their specific operational needs and processes.

Supply chain management becomes more complex as your business grows. What works for 50 orders per day breaks down at 500. Effective management directly impacts your ability to control costs, meet customer expectations, and compete successfully in your market.

This guide explains supply chain management fundamentals, covering key components, modern technologies, common challenges, and practical strategies you can use to improve your operations and build more resilient systems.

What is supply chain management?

Supply chain management coordinates all activities involved in moving products from raw materials to customers. This includes selecting suppliers, managing production, controlling inventory, organizing transportation, and handling returns.

For instance, when a furniture retailer receives a customer order, the supply chain coordinates lumber suppliers, manufacturing facilities, warehouse storage, delivery trucks, and potentially return logistics if issues arise.

How is supply chain management different from logistics?

Logistics handles the physical movement and storage of goods, like transportation, warehousing, and delivery operations. Supply chain management includes logistics but extends much further to cover strategy, planning, supplier relationships, production coordination, and demand forecasting across all partners.

Think of logistics as one important function within the larger supply chain framework. While logistics teams optimize delivery routes and manage warehouse operations, supply chain management coordinates all partners and processes from initial sourcing decisions through final customer delivery and potential returns.

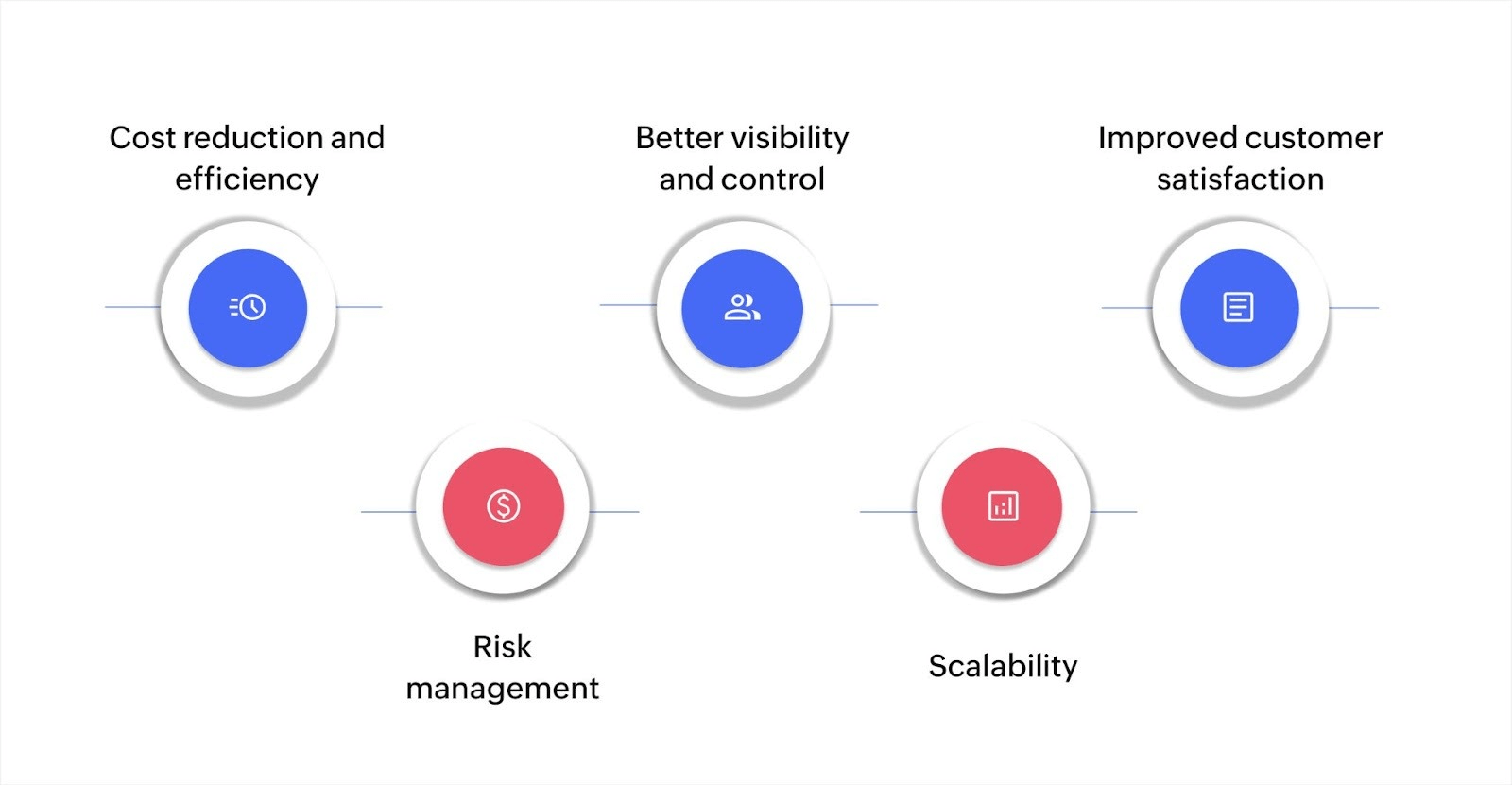

Why is supply chain management important?

Supply chain management directly affects your profit margins, operational speed, and market position. In fact, recent industry data shows that businesses with well-managed supply chains spend 15% less on operations, hold half the inventory, and complete cash cycles three times faster.

Here are some of the top reasons why effective supply management is essential.

Lower operational expenses

Better coordination reduces waste, excess inventory, and unnecessary transportation expenses. When you can see what's happening across your supply chain, you can identify bottlenecks, remove redundant steps, and optimize resource use. For instance, accurate demand forecasts prevent overproduction while ensuring you have enough stock to meet actual orders.

Real-time tracking and oversight

Real-time information about inventory levels, shipment status, and supplier performance lets you make informed decisions quickly. When a supplier faces delays, you can adjust production schedules or activate backup suppliers before customer commitments are affected. This visibility also helps you identify patterns and improvement opportunities.

Reliable delivery and service

Reliable delivery builds customer trust and repeat business. When your supply chain operates smoothly, products arrive on time, orders are accurate, and customers can track their shipments. This reliability creates a competitive advantage in markets where customers have many options.

Disruption management

Supply disruptions can happen anywhere at anytime, like natural disasters, supplier issues, and transportation problems. Effective management includes backup plans, alternative suppliers, and flexible operations that can adapt when problems occur. Companies with strong supply chain management recover faster from disruptions.

Supporting business growth

As your business grows, your supply chain needs to handle increased volume without proportional cost increases. Well-designed systems and processes can scale efficiently, supporting growth in sales and market expansion without operational chaos or overwhelming coordination requirements.

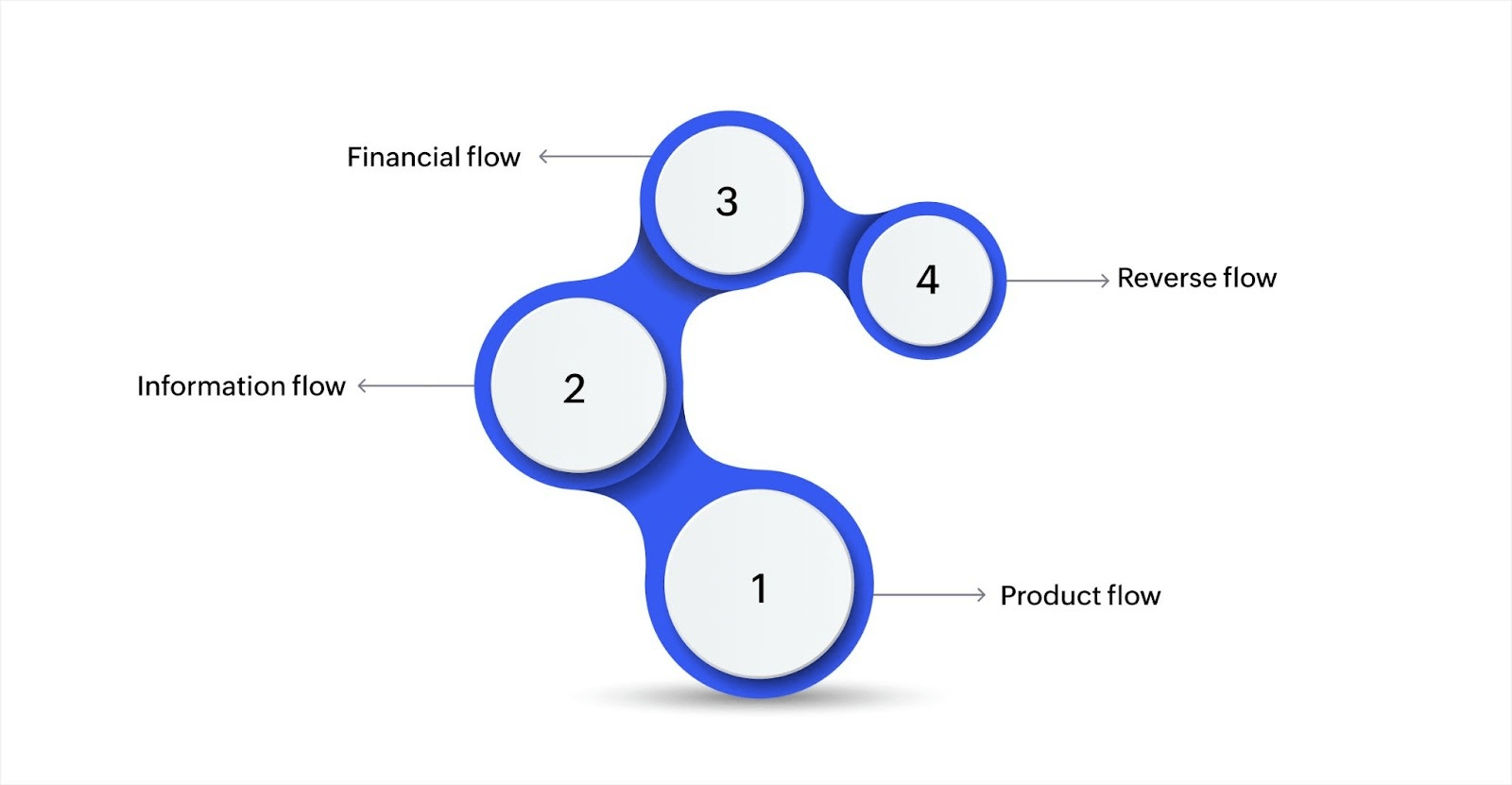

The four key flows in supply chain management

Supply chains function through four interconnected flows working together continuously. Understanding these flows helps you identify where coordination problems occur and how to improve overall performance.

1. Product flow

Physical goods move from raw materials through manufacturing to customers. This includes transportation between locations, storage in warehouses, quality checks, packaging, and final delivery. For instance, a consumer electronics company coordinates component shipments from multiple suppliers, assembly operations, distribution center storage, and delivery to retail stores or customers.

2. Information flow

Data moves in both directions throughout the supply chain. Suppliers need order forecasts, manufacturers need production schedules, warehouses need inventory updates, and customers need shipment tracking. When information flows smoothly, everyone can plan and coordinate their activities effectively.

3. Financial flow

Money moves through payment processing, invoicing, credit terms, and cost accounting. This includes purchase payments to suppliers, production costs, logistics expenses, and revenue collection from customers. Managing cash flow well across your supply chain ensures you can pay suppliers on time while maintaining working capital.

4. Reverse flow

Products sometimes return through warranty claims, defects, recalls, or end-of-life recycling. Handling returns efficiently affects customer satisfaction and cost control. For example, an appliance manufacturer needs processes to receive returned units, determine refunds or replacements, repair or dispose of products, and track return patterns to identify quality issues.

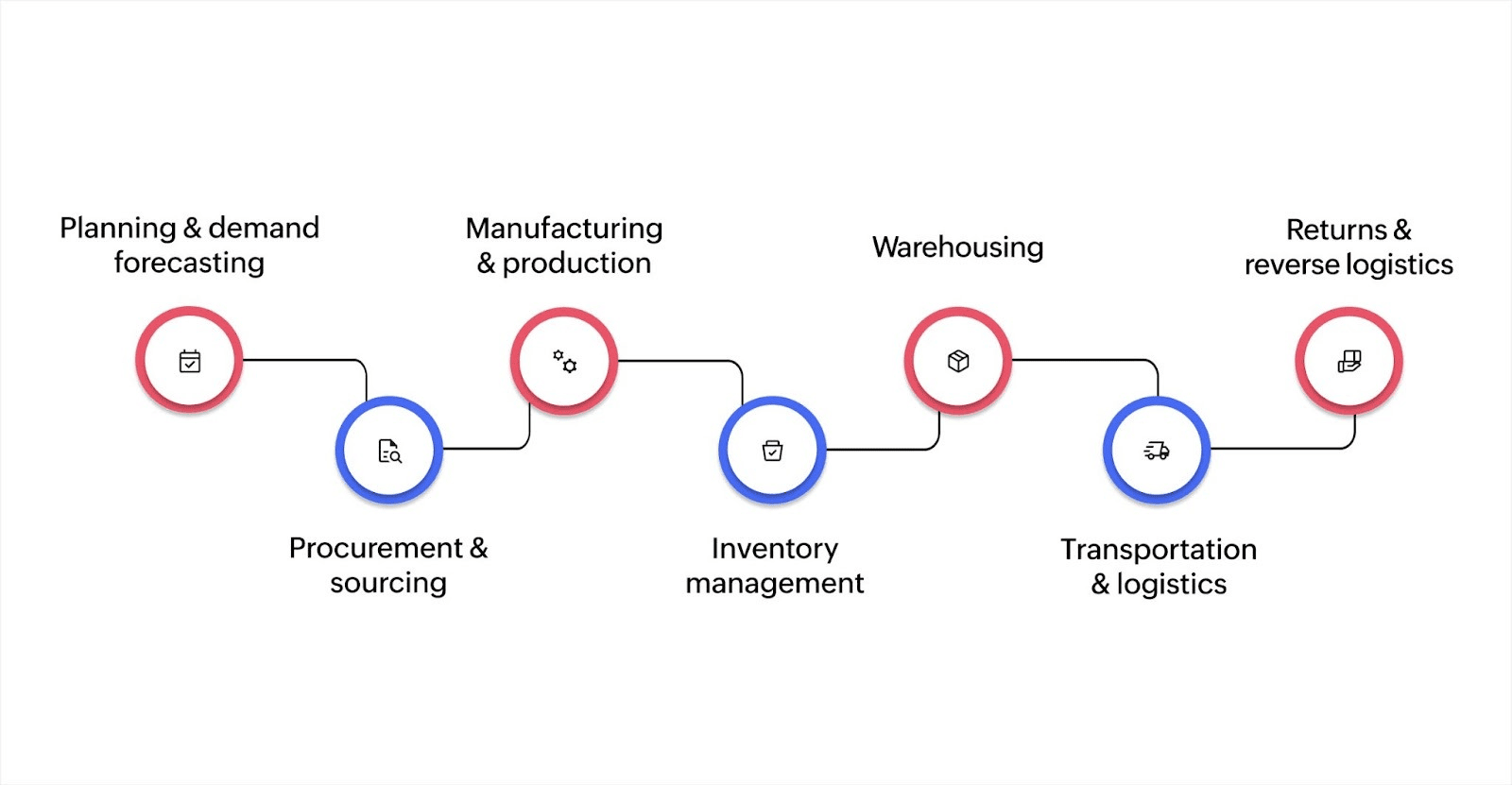

7 essential components of supply chain management

Several interconnected components work together to move products from suppliers to customers. Managing each component well and coordinating between them creates efficient, reliable operations.

1. Planning and demand forecasting

Predicting future demand guides all other supply chain decisions. Analysis of historical sales data, market trends, seasonal patterns, and external factors helps you estimate what products you'll need and when. For instance, a sporting goods retailer analyzes past sales to forecast demand for camping equipment before the summer season.

2. Procurement and sourcing

Selecting suppliers and purchasing materials requires evaluating vendor reliability, pricing, quality standards, and delivery capabilities. Strong relationships with suppliers create stability, while backup options provide flexibility when issues arise. Procurement also includes contract negotiation and ongoing performance monitoring.

3. Manufacturing and production

Converting raw materials into finished products involves scheduling production runs, managing work-in-progress inventory, maintaining equipment, and controlling quality. Coordination with procurement and logistics teams ensures materials arrive when needed and finished goods move to warehouses efficiently.

4. Inventory management

Balancing stock levels to meet demand without excess costs requires constant attention. Too much inventory ties up capital and creates storage expenses. Too little causes stockouts and lost sales. For example, a pharmaceutical distributor tracks expiration dates and usage rates to maintain adequate supplies without waste.

5. Warehousing

Storage facilities organize products, manage incoming and outgoing shipments, and prepare orders for delivery. Efficient warehouse operations use space effectively, minimize handling time, and maintain accurate inventory records. Location decisions affect transportation costs and delivery speed.

6. Transportation and logistics

Moving products between locations involves selecting carriers, planning routes, coordinating deliveries, and tracking shipments. Optimizing transportation balances speed, cost, and reliability. For instance, a furniture manufacturer might use trucks for regional deliveries but switch to rail for cross-country shipments to reduce costs.

7. Returns and reverse logistics

Processing returned products requires receiving items, evaluating their condition, determining refunds or replacements, and handling disposal or refurbishment. Efficient returns processing affects customer satisfaction and product value recovery. Tracking return patterns also identifies quality issues or product improvements needed.

Types of supply chain management approaches

Your choice of supply chain management strategy depends on factors such as product characteristics, demand patterns, cost priorities, and the level of flexibility you need to respond to change. Here's how the main approaches compare:

| Approach | Primary focus | Best for | Key trade-off |

| Lean | Cost reduction and waste elimination | Stable demand, predictable markets | Lower costs but less flexibility |

| Agile | Speed and flexibility | Unpredictable demand, fast-changing markets | Higher costs but quick adaptation |

| Resilient | Risk management and continuity | Markets with frequent disruptions | Redundancy costs but better stability |

| Green | Environmental sustainability | Companies with sustainability mandates | Implementation investment but reduced environmental impact |

| Digital | Data-driven coordination | Complex operations requiring visibility | Technology investment, but better decision-making |

Each approach offers distinct advantages depending on your operational priorities and market environment.

Lean supply chain

This approach minimizes waste and reduces costs by keeping inventory levels low and optimizing every process step. Companies following lean principles focus on efficiency, eliminating activities that don't add value.

One common practice involves ordering materials timed precisely to production needs rather than maintaining large stockpiles. For example, an auto parts manufacturer coordinates component deliveries to arrive right before assembly, reducing storage costs while maintaining production flow.

Agile supply chain

Flexibility and speed define this strategy, letting businesses respond quickly to demand changes or market shifts. Organizations using agile methods can adjust production volumes, change product mixes, or activate alternative suppliers with minimal delay.

This works particularly well in industries where customer preferences change rapidly or product lifecycles are short. Fashion retailers, for instance, need agility to respond to trending styles and adjust inventory before preferences shift again.

Resilient supply chain

Building redundancy and backup options helps companies handle disruptions without operational failures. This approach involves maintaining safety stock beyond immediate needs, developing relationships with multiple suppliers for critical items, and creating contingency plans for various scenarios.

While these measures cost more than lean operations, they provide stability when suppliers face problems or transportation routes become unavailable. Manufacturers of essential products often choose resilience over cost optimization.

Green supply chain

Sustainability focus means reducing environmental impact through energy-efficient transportation, waste reduction initiatives, recyclable packaging, and ethical sourcing practices.

Companies adopting green strategies evaluate suppliers based on environmental standards alongside traditional metrics like cost and quality. For instance, a food company might work with local suppliers to reduce transportation emissions and ensure fair labor practices, even when global suppliers offer lower prices.

Digital supply chain

Technology integration connects all partners and processes through shared data platforms, automation tools, and analytics capabilities. This approach provides real-time visibility across the entire supply chain, enables predictive maintenance on equipment, and supports data-driven decision-making.

Organizations using digital methods can spot problems earlier, coordinate responses faster, and optimize operations based on actual performance data rather than estimates or assumptions.

Best practices for effective supply chain management

Improving supply chain performance requires deliberate strategies and consistent execution. These practices help businesses build more efficient, resilient operations. Here's what works well:

- Use data for decisions - Track metrics like inventory turnover, order fulfillment time, supplier performance, and transportation costs to guide improvements and identify problems early.

- Build supplier relationships - Develop partnerships with reliable suppliers through clear communication, fair terms, and mutual trust while maintaining backup options for critical items.

- Improve coordination - Connect teams across procurement, production, warehousing, and logistics through shared systems and regular communication to prevent gaps and delays.

- Manage inventory efficiently - Balance stock levels using techniques like ABC analysis to prioritize high-value items while maintaining safety stock for critical products.

- Plan for disruptions - Create contingency plans identifying alternative suppliers, backup transportation options, and response procedures for various disruption scenarios.

- Monitor performance - Review key metrics regularly to spot trends, measure improvement initiatives, and hold partners accountable to agreed standards and delivery commitments.

- Keep improving - Continuously evaluate processes, gather feedback from teams and partners, test new approaches, and implement changes that reduce costs or improve service levels.

How supply chain management looks across different industries

Supply chain priorities and challenges shift significantly across industries based on product characteristics, regulatory requirements, and customer expectations. Here's how supply chain management varies across major industries:

| Industry | Critical priority | Main challenge | Technology focus |

| Retail | Inventory turnover and stock availability | Managing thousands of SKUs (stock keeping units) with seasonal demand | Demand forecasting and omnichannel coordination |

| Manufacturing | Supplier coordination and quality control | Synchronizing component deliveries for production | Production planning and supplier tracking |

| Healthcare | Product safety and regulatory compliance | Temperature control and expiration management | Traceability and cold chain monitoring |

| Food and beverage | Freshness and quality preservation | Minimizing spoilage across distribution | Cold chain management and rapid fulfillment |

| Technology | Speed to market and component availability | Managing complex global supplier networks | Supply risk monitoring and shortage prediction |

| Automotive | Just-in-time delivery and quality standards | Coordinating hundreds of component suppliers | Supplier integration and production synchronization |

Technology's role in supply chain management

Modern supply chains generate massive amounts of data from suppliers, warehouses, transportation systems, and customer orders. Technology helps businesses collect, analyze, and act on this information in ways that manual tracking simply can't match, turning data into coordination and visibility.

Here's how specific technologies improve operations.

Cloud-based platforms

Web-accessible systems give suppliers, warehouses, logistics providers, and internal teams access to current information from anywhere. This shared visibility improves coordination and speeds up decision-making.

For instance, when inventory levels drop below thresholds, purchasing teams see alerts immediately and can reorder before stockouts occur.

Automation tools

Software handles repetitive tasks like order processing, invoice generation, inventory updates, and shipment scheduling. Automation reduces errors, frees staff for higher-value work, and speeds up operations.

For example, a distribution company can use low-code app development platforms like Zoho Creator to build automated workflows that trigger purchase orders when inventory hits reorder points, send approval notifications to managers, and update financial systems without manual data entry between steps.

Artificial intelligence (AI)

AI analyzes patterns in historical data to predict future demand, identify potential disruptions, and recommend actions. Machine learning improves forecast accuracy over time by learning from past prediction errors.

For example, a goods retailer can use AI to analyze three years of sales data alongside weather patterns and local events to predict which products will see increased demand in specific regions during the upcoming months.

Internet of Things (IoT)

Sensors attached to products, vehicles, and equipment provide real-time tracking and monitoring. IoT devices can track shipment locations, monitor temperature for sensitive goods, or alert teams when equipment needs maintenance.

For instance, a pharmaceutical distributor can use temperature sensors throughout warehouses and delivery trucks to ensure medications remain within required ranges and receive immediate alerts when conditions deviate.

Analytics and reporting

Data analysis tools identify trends, measure performance, and highlight problems. Visual dashboards show key metrics like order fulfillment rates, inventory turnover, supplier performance, and transportation costs.

For example, a manufacturing company can use analytics dashboards to spot that a particular supplier consistently delivers two days late, prompting conversations about improvement or evaluation of alternative vendors before the delays affect production schedules.

Build custom supply chain solutions with Zoho Creator

Managing supply chains with spreadsheets, disconnected tools, and manual coordination creates visibility issues and slows decision-making. As operations grow, these limitations lead to more problems, such as delayed issue responses, data-entry errors, and coordination failures between teams and partners.

Zoho Creator is an AI-powered, low-code application development platform that helps businesses build custom supply chain solutions to match their specific processes and requirements. You can create applications for procurement tracking, inventory management, supplier coordination, or logistics monitoring without extensive coding knowledge.

Operations teams can start building solutions quickly without waiting months for IT resources or spending heavily on consultants. Sign up for free today to see what you can build in minutes.

FAQ

How long does it take to implement new supply chain software?

Implementation timelines vary from weeks to months based on system complexity and integration requirements. Low-code platforms can go live faster than traditional software because they require less custom development and technical configuration.

What metrics should you track in supply chain management?

Focus on inventory turnover, order fulfillment time, supplier delivery performance, transportation costs, and stock accuracy. These metrics reveal operational efficiency and highlight areas needing improvement without overwhelming teams with excessive data.

How do you choose the right supply chain model?

Match your approach to your business needs and market conditions. Products with stable demand work well with lean models while unpredictable markets require agile approaches. Consider factors like cost priorities, customer expectations, and disruption risks.

What causes most supply chain disruptions?

Supplier issues, transportation problems, natural disasters, and demand fluctuations create most disruptions. Single-source dependencies increase vulnerability. Building backup options and monitoring suppliers helps reduce the disruption impact.

How often should you review supplier performance?

Monthly reviews work well for critical suppliers, while quarterly assessments suit less critical partners. Track metrics like delivery reliability, quality rates, and responsiveness continuously to identify problems early.

Stephen

StephenStephen is a product marketer at Zoho Creator. An avid writer, he plies his trade evangelizing low-code during the day and pens songs at night. Sneakerhead and sushi enthusiast too.