- HOME

- Know Your Tech

- Facility management: Types, digitization steps, and KPIs

Facility management: Types, digitization steps, and KPIs

- Last Updated : February 2, 2026

- 351 Views

- 10 Min Read

Managing facilities manually works fine until you add a second location or double your equipment inventory. Suddenly, spreadsheets can't keep up, and paper forms go missing. The systems that worked for smaller operations create bottlenecks as complexity increases.

Highlights

- Facility management (FM) coordinates physical assets, infrastructure, people, and processes to ensure buildings operate safely, efficiently, and cost-effectively.

- Hard FM focuses on building systems and infrastructure, while Soft FM handles occupant services and support functions.

- Integrated facility management (IFM) combines hard and soft services under a single provider, leveraging shared digital infrastructure to improve coordination.

- Digital transformation in facility management reduces manual coordination, improves visibility, and enables data-driven decisions across operations.

- Key performance indicators like response times, maintenance backlog, and energy consumptionper square foot measure facility management effectiveness.

Facility management provides the structure needed to coordinate physical assets, infrastructure maintenance, occupant services, and vendor relationships at scale. Modern organizations use facility management to maintain safe environments, optimize resources, and support business operations across growing portfolios.

This blog post walks you through facility management essentials, including service models, practical digitization steps, and key performance indicators. You'll learn effective approaches to improve operations, reduce costs, and prepare your facilities for growth.

What is facility management?

Facility management involves organizing people, places, processes, and technology to keep buildings safe, efficient, and affordable to operate. The discipline combines strategic planning with daily operations to maintain physical environments that support business objectives.

The scope covers everything from HVAC and electrical systems to cleaning services and security operations. Facility management handles both technical infrastructure and occupant services, ensuring that physical spaces meet operational needs while controlling costs and maintaining regulatory compliance.

For instance, a healthcare facility can use facility management to coordinate medical equipment maintenance, patient room cleaning schedules, HVAC systems for infection control, and emergency power systems, all while meeting strict health regulations.

Types of facility management and service models

Knowing different facility management approaches helps you choose the right structure for your organization. The field divides into distinct service types and delivery models, each addressing specific operational needs.

Hard vs. Soft facility management

Here's how Hard FM and Soft FM differ:

| Aspect | Hard FM | Soft FM |

| Focus | Building infrastructure and technical systems | Occupant services and support functions |

| Core services | HVAC, electrical, plumbing, fire safety, elevators, building automation | Cleaning, security, catering, waste management, reception, landscaping |

| Required expertise | Technical and engineering knowledge | Service management and customer experience |

| Maintenance type | Equipment maintenance, system repairs, infrastructure upgrades | Daily service delivery, scheduled cleaning, visitor management |

| Impact on operations | Building functionality and safety | Occupant comfort and workplace experience |

Hard FM focuses on building infrastructure and technical systems. It requires specialized technical knowledge and handles the physical components that keep buildings functional.

Soft FM covers occupant services and support functions. It emphasizes the human experience and daily comfort within facilities.

For instance, an office building's Hard FM team maintains the HVAC system, monitors electrical panels, and services elevator equipment. The Soft FM team manages daily cleaning, coordinates security patrols, handles reception services, and maintains the landscape. Both functions work together to create a safe, comfortable environment.

In-house, outsourced, and integrated facility management

Organizations can structure facility management in different ways based on their needs, resources, and strategic priorities. Here's how these service models compare:

| Model | Management approach | Best for | Key advantages | Common challenges |

| In-house FM | Internal teams manage all operations | Core facilities requiring direct control | Direct oversight, institutional knowledge, cultural alignment | Higher overhead, limited specialized expertise |

| Outsourced FM | Third-party providers manage specific services | Non-core functions or specialized services | Expert knowledge, cost flexibility, scalable resources | Less direct control, potential communication gaps |

| Integrated FM (IFM) | Single provider manages both hard and soft services | Multi-location operations requiring coordination | Unified accountability, simplified vendor management, shared systems | Provider dependency, transition complexity |

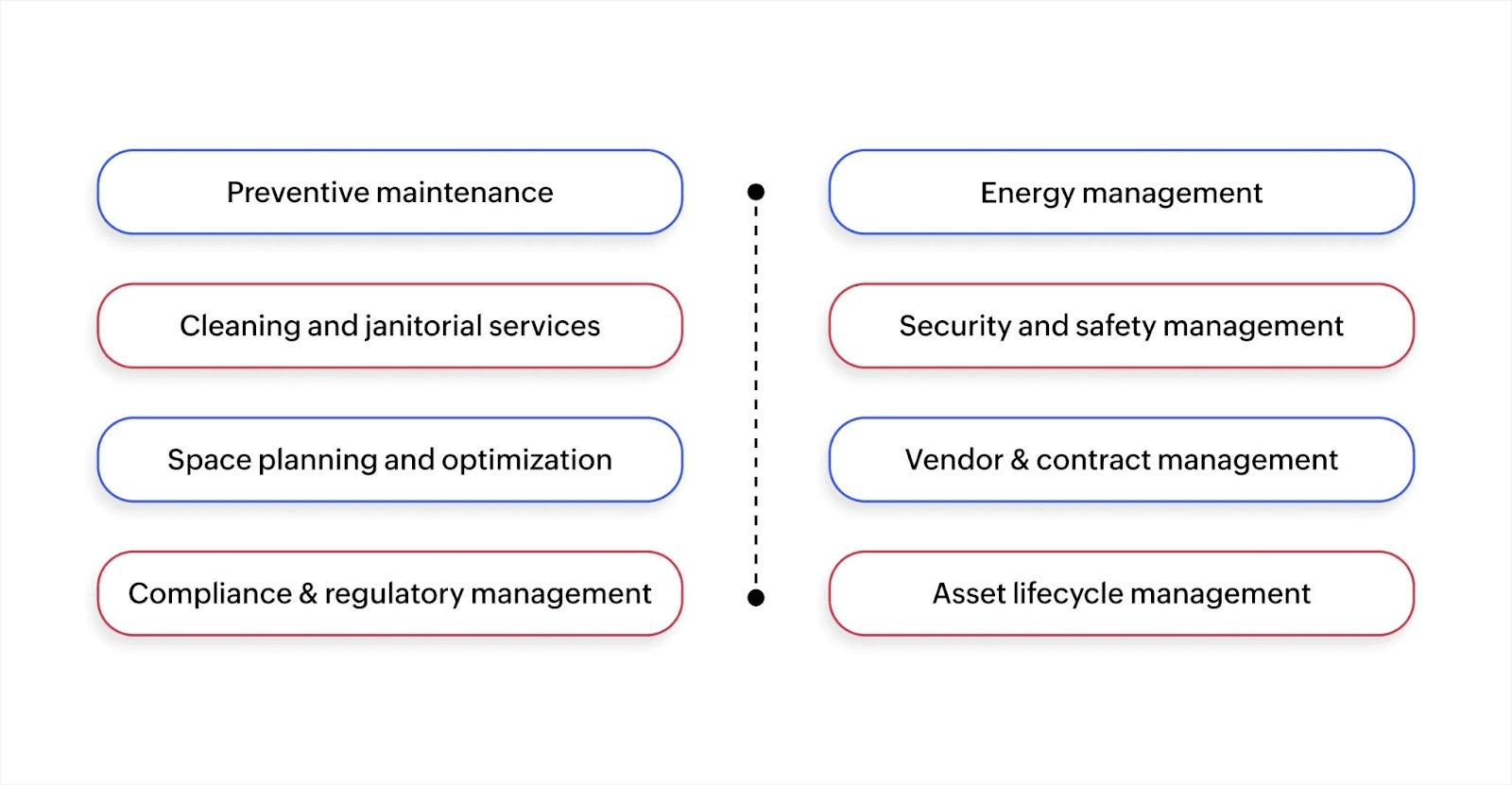

Essential facility management services

Facility management encompasses multiple services that keep buildings operational and support business activities. These services work together to maintain safe, efficient, comfortable environments.

Here are the core services:

- Preventive maintenance: Schedule regular inspections and maintenance to avoid equipment failures and extend asset life.

- Energy management: Monitor and reduce energy consumption through smart systems, efficient lighting, and optimized HVAC operations.

- Cleaning and janitorial services: Maintain clean, healthy environments that support employee well-being and create positive impressions for visitors.

- Security and safety management: Protect people and property through access control, surveillance systems, emergency response planning, and safety compliance.

- Space planning and optimization: Design efficient layouts, manage office moves, and adapt spaces as business needs change.

- Vendor and contract management: Coordinate third-party service providers, track performance, and manage contracts and service level agreements.

- Compliance and regulatory management: Ensure facilities meet safety codes, environmental regulations, and industry-specific requirements through regular audits and documentation.

- Asset lifecycle management: Track equipment from purchase through maintenance to replacement, optimizing total cost of ownership.

These services support daily operations while contributing to long-term strategic goals like cost control, regulatory compliance, and workplace experience.

Key benefits of effective facility management

Well-executed facility management creates measurable improvements across operations, costs, and workplace quality. Knowing these benefits helps justify investment in modern facility management approaches.

Lower operational costs

Proactive maintenance prevents expensive emergency repairs and extends equipment life. Regular HVAC inspections, for instance, catch minor issues before compressors fail, avoiding costly replacements during peak cooling season.

Energy management through smart systems and efficient equipment reduces utility bills. Optimized vendor contracts and consolidated services eliminate redundant spending.

Improved operational efficiency

Organized systems reduce the time teams spend coordinating tasks and tracking information. Automated scheduling ensures maintenance happens on time without manual follow-up.

Centralized data allows technicians to access equipment history instantly instead of searching through files. Field teams complete more work when mobile systems provide immediate access to work orders and asset information.

According to recent data, the facility management market was valued at USD 1.46 trillion in 2024, with forecasts indicating it will grow to USD 2.38 trillion by 2034. Organizations across industries are investing more in facility management as operations become more complex and efficiency demands increase.

Better regulatory compliance

Facility management ensures organizations meet safety codes, environmental regulations, and industry requirements. Automated compliance tracking monitors inspection schedules, documents maintenance activities, and maintains audit trails.

For instance, regular fire safety inspections, documented HVAC filter changes, and tracked equipment testing demonstrate compliance during regulatory audits. This reduces the risk of fines and legal issues while protecting occupants.

Extended asset lifespan

Preventive maintenance programs based on manufacturer guidelines and usage patterns keep equipment operating longer. Regular servicing prevents wear and tear from causing premature failures.

For instance, scheduled pump maintenance, bearing lubrication, and belt replacements extend HVAC system life by years compared to run-to-failure approaches. This maximizes return on capital investments and improves budget predictability.

Enhanced workplace experience

Well-maintained facilities with comfortable temperatures, clean spaces, and quickly resolved issues create positive work environments. Employees stay productive when systems work reliably and problems get addressed promptly.

For instance, rapid response to comfort complaints, consistent cleaning schedules, and functional equipment support satisfaction and retention. Quality facility management directly affects how people experience their workplace.

Improved sustainability

Energy efficiency measures, waste reduction programs, and sustainable practices lower environmental impact while reducing costs. Smart building systems optimize energy use, LED lighting cuts consumption, and recycling programs reduce waste disposal fees.

These improvements help organizations meet corporate sustainability goals and environmental regulations while controlling operational expenses.

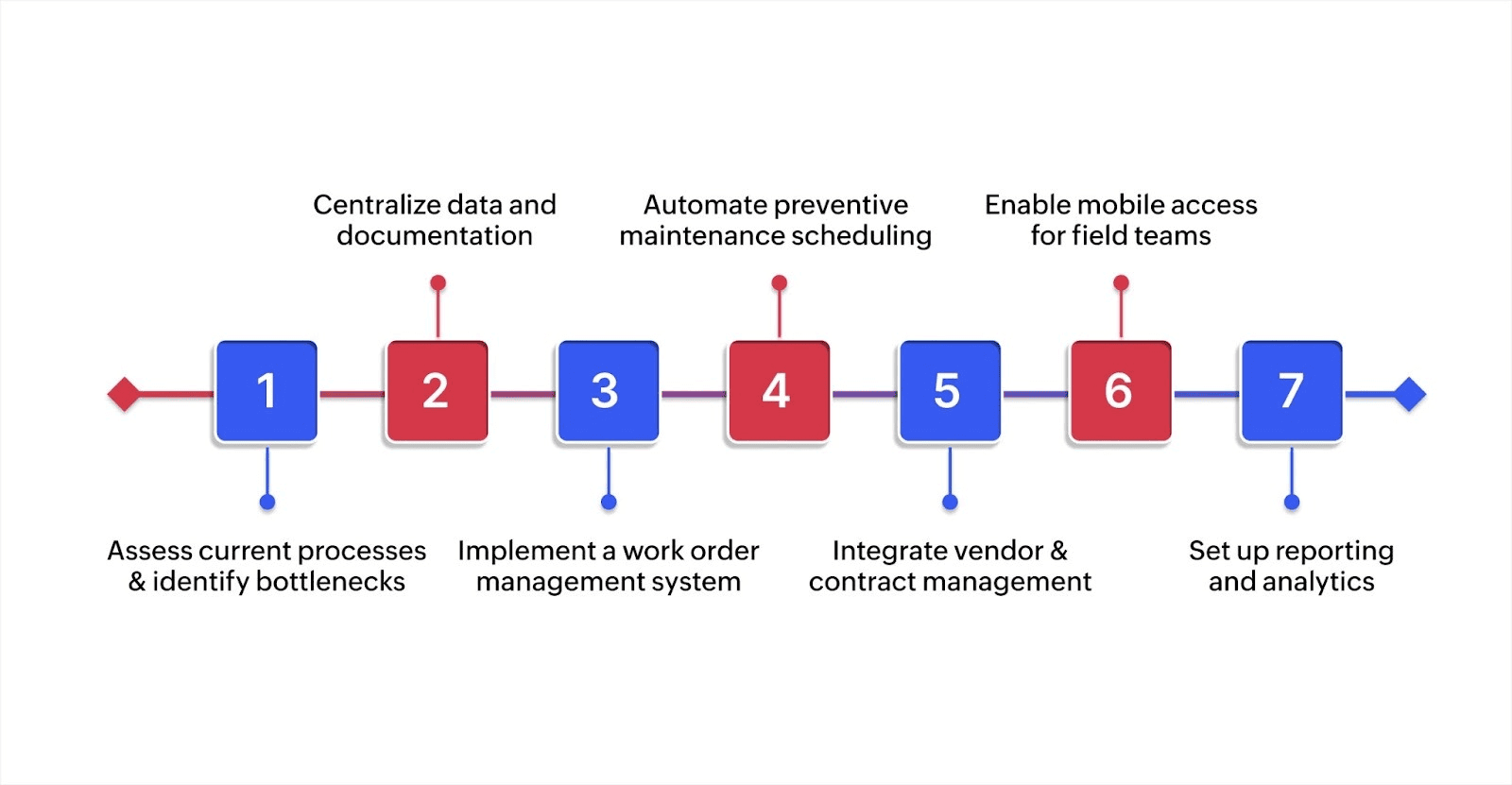

How to digitize and automate facility management

Digital transformation in facility management replaces manual processes with automated systems that improve efficiency, visibility, and decision-making. Following a structured approach ensures successful implementation.

Step 1: Assess current processes and identify bottlenecks

Map existing workflows for maintenance requests, work order completion, asset tracking, and vendor management. Document how information flows between teams and where delays occur.

For instance, track how long maintenance requests sit before assignment, how often teams duplicate work due to poor communication, or where paper forms create bottlenecks. This assessment reveals priority areas for digital improvement.

Step 2: Centralize data and documentation

Consolidate asset information, equipment specifications, maintenance histories, and vendor contracts into a single system.

Digitize paper records, migrate data from spreadsheets, and create a unified database accessible to all relevant teams. This eliminates scattered information and reduces time spent searching for details.

Step 3: Implement a work order management system

Replace paper forms and email requests with digital work order submission, assignment, and tracking. Set up automated routing based on request type, location, and technician availability. Configure notifications to alert teams when new requests arrive, deadlines approach, or work is completed.

For instance, when an employee submits a maintenance request through a mobile app, the system automatically assigns it to the appropriate technician and sends confirmation to the requester.

Step 4: Automate preventive maintenance scheduling

Configure recurring maintenance tasks based on equipment requirements, manufacturer recommendations, and usage patterns. Set up automatic reminders for upcoming service, track completion, and log maintenance activities.

For instance, the system automatically creates monthly filter change orders, quarterly equipment inspections, and annual safety tests without manual scheduling.

Step 5: Integrate vendor and contract management

Centralize vendor information, service level agreements, and performance metrics. Track contract terms, renewal dates, and spending by vendors.

Monitor service quality through automated feedback collection and performance reporting. Set up automatic notifications for upcoming contract renewals to avoid service gaps.

Step 6: Enable mobile access for field teams

Provide mobile applications that let technicians access work orders, view asset information, update task status, and capture photos while in the field.

Mobile access eliminates trips back to offices to retrieve information or update systems, improving response times and work completion rates.

Step 7: Set up reporting and analytics

Configure dashboards that display key metrics like work order volumes, completion rates, maintenance costs, and asset performance.

Generate automated reports for management review, compliance documentation, and budget planning. Use data to identify trends, spot problems early, and make informed decisions about resource allocation and capital planning.

Key facility management KPIs to track

Measuring facility management performance helps identify improvement opportunities and demonstrate value to stakeholders. These metrics provide objective data for decision-making and resource allocation.

Here are the essential KPIs that facility managers should monitor:

| KPI | What it measures | Why it matters | Example target range |

| Average response time | Time from request submission to work order assignment | Indicates team responsiveness and workload balance | Under 2 hours for urgent, under 24 hours for routine |

| Maintenance backlog | Pending work orders as a percentage of total requests | Reveals capacity issues and resource constraints | Below 10% of total work orders |

| Preventive vs reactive maintenance ratio | Planned maintenance vs. emergency repairs | Assesses proactive management effectiveness | 80% preventive, 20% reactive |

| Energy consumption per square foot | Utility usage normalized by space | Identifies efficiency opportunities and cost control | Varies by building type and location |

| Asset uptime percentage | Equipment availability and operational time | Evaluates maintenance program effectiveness | Above 95% for critical assets |

| Work order completion rate | Percentage of tasks completed on time | Measures team performance and resource allocation | Above 90% on-time completion |

| Maintenance cost per asset | Spending on individual equipment pieces | Identifies replacement candidates and budget optimization | Compare against replacement cost |

| Occupant satisfaction scores | Feedback on facility services and comfort | Measures workplace experience quality | Above 80% satisfaction rating |

Regular KPI monitoring reveals trends before they become problems. For instance, increasing response times might indicate understaffing, rising reactive maintenance could signal inadequate preventive programs, or declining satisfaction scores might point to service quality issues requiring attention.

Best practices for efficient facility management

Implementing proven practices improves facility management performance and prepares operations for growth. These approaches address common challenges and support continuous improvement.

Adopt preventive maintenance programs

Schedule regular inspections and maintenance based on equipment requirements, manufacturer guidelines, and usage patterns. Track completion and document activities to build maintenance histories.

For instance, set up monthly HVAC filter changes, quarterly pump inspections, and annual safety system tests. Preventive programs reduce emergency repairs, extend equipment life, and lower overall maintenance costs.

Standardize processes and documentation

Create consistent procedures for common tasks like work order processing, maintenance activities, and compliance checks. Document workflows, maintain procedure manuals, and use standard forms.

Standardization improves training effectiveness, ensures quality consistency, and makes it easier for team members to cover for each other.

Use data to make decisions

Track performance metrics, analyze trends, and identify patterns in equipment failures, maintenance costs, and energy consumption. Use this information to adjust maintenance frequencies, schedule equipment replacements, and allocate resources.

For instance, if data shows certain equipment consistently fails between scheduled maintenance, adjust service intervals to catch issues earlier.

Improve communication between teams

Use centralized platforms that let operations staff, technicians, vendors, and management share information in real time. Replace email chains and phone calls with systems that provide status updates, track task completion, and maintain conversation history. Mobile access ensures field teams stay connected even when away from offices.

Plan for scalability

Design systems and processes that handle increasing volumes without requiring proportional resource growth. Automation should accommodate more locations, assets, and users without manual bottlenecks.

For instance, when a retail company expands from 10 to 50 locations, its facility management system should handle the increased volume without needing complete rebuilding.

Automate facility operations with Zoho Creator

Managing facility operations across multiple locations becomes complex when you rely on spreadsheets, paper forms, and disconnected systems. Maintenance requests get lost, asset data becomes outdated, and compliance tracking requires constant manual effort. Your team spends more time coordinating tasks than actually completing them.

Zoho Creator is an AI-powered, low-code application development platform that lets you build custom applications to automate your facility operations without extensive coding. You can create tailored solutions that match your exact workflows, centralize work orders, track assets, manage vendors, and monitor compliance in one accessible system.

The visual interface lets you design custom forms, create automated workflows, set up approval processes, and generate real-time reports and dashboards without writing complex code. When your needs change, you can update applications yourself without waiting for developers.

FAQ

1. What is the difference between facility management and facility maintenance?

Facility management is the complete approach to coordinating people, spaces, processes, and technology for efficient building operations. Facility maintenance focuses specifically on the physical upkeep, repairs, and preventive care of equipment and infrastructure.

2. What does a facility manager do?

A facility manager oversees daily building operations, coordinates maintenance activities, manages vendor relationships, ensures regulatory compliance, and aligns facility operations with business objectives. They handle everything from work order management to budget control.

3. How do you handle facility management across multiple time zones?

Use cloud-based systems that automatically adjust timestamps to local time zones while maintaining centralized reporting. Set up role-based access so regional teams manage local operations while corporate teams monitor performance across all locations through unified dashboards.

4. What security features should facility management software include?

Essential security features include role-based access controls, data encryption, audit trails tracking user actions, automatic backups, multi-factor authentication, and IP restrictions. These protections ensure sensitive facility data, vendor contracts, and compliance records remain secure from unauthorized access.

5. How do you measure ROI on facility management investments?

Track metrics like reduced emergency repair costs, lower energy consumption, improved work order completion rates, and decreased equipment downtime. Compare these savings against your investment in software, training, and implementation to calculate the ROI.

Stephen

StephenStephen is a product marketer at Zoho Creator. An avid writer, he plies his trade evangelizing low-code during the day and pens songs at night. Sneakerhead and sushi enthusiast too.